braggs used cars

Today, tin plate ceiling manufacturers combine traditional craftsmanship with cutting-edge technology. The process begins with high-quality steel sheets that are coated with a layer of tin to prevent rust and corrosion. Manufacturers have started integrating advanced techniques such as computerized laser cutting to create intricate designs, ensuring precision and consistency. This modern approach allows for customizable options that cater to contemporary tastes while retaining the classic appeal of tin ceilings.

tin plate ceiling manufacturers

2. Corrosion Resistance Many metal flashing products are treated with protective coatings or are made from materials like aluminum or stainless steel, which are naturally resistant to rust and corrosion. This property ensures that the flashing maintains its performance and appearance over time, which is crucial for maintaining roof integrity.

flashing roof metal sheet manufacturer

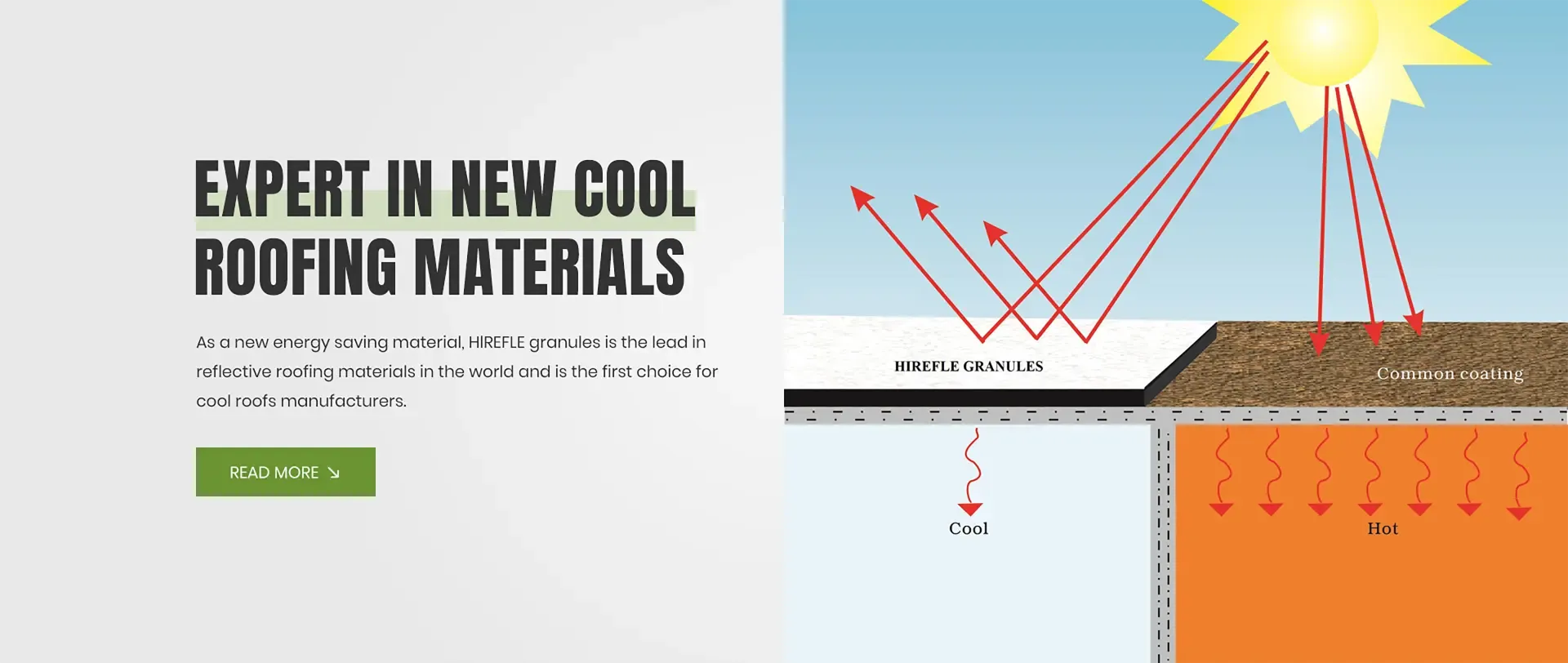

Moreover, energy-efficient roof coatings can help in reducing cooling costs. By reflecting sunlight rather than absorbing it, these coatings help maintain lower temperatures in your attic and living spaces. This not only enhances comfort but also reduces reliance on air conditioning systems, leading to lower energy bills.

roof shingle coatings

4. Insulation Properties Some felt roofing systems come with added insulation benefits. Insulation can help regulate the temperature inside the conservatory, keeping it warm in winter and cool in summer. This aspect can make the conservatory more comfortable year-round and reduce energy costs.

conservatory felt roof